The concept of remote work has become a transformative force across various industries, with technological advancements enabling workers to perform tasks from anywhere in the world. While remote work is often associated with office-based jobs, it has also made significant inroads in industries that require fieldwork, such as the offshore and subsea sectors.

One of the most groundbreaking developments in this area is the rise of Remotely Operated Vehicles (ROVs), which are transforming underwater maintenance and inspection processes. By enabling operators to conduct complex subsea tasks from the safety and comfort of the surface, ROVs are making underwater maintenance not only safer but also more efficient.In this article, we explore how ROVs are revolutionizing underwater maintenance and how their integration into remote work processes is changing the way offshore industries operate.

What Are ROVs and How Do They Work?

Remotely Operated Vehicles (ROVs) are unmanned submersibles that are remotely controlled by operators located on the surface, typically aboard ships, offshore platforms, or onshore control rooms. Unlike autonomous underwater vehicles (AUVs), which can operate independently, ROVs require human oversight for navigation, task execution, and data analysis. Equipped with high-definition cameras, sonar systems, robotic arms, and specialized tools, ROVs are used for a wide range of underwater tasks, such as:

- Inspection and monitoring of underwater structures like oil rigs, pipelines, and cables.

- Maintenance and repairs on subsea infrastructure.

- Environmental monitoring, including collecting samples from the seafloor and measuring water quality.

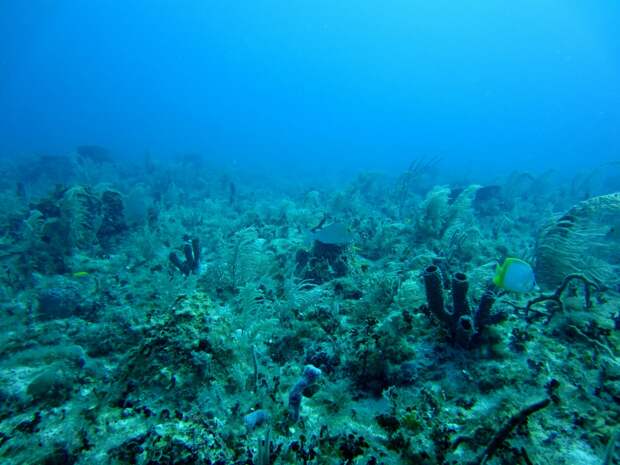

- Surveying and mapping underwater environments for scientific or resource extraction purposes.

ROVs are typically tethered to the surface vessel via an umbilical cable that provides power and transmits data back to the operator. However, some newer systems use wireless technology to reduce the dependence on tethers, offering more flexibility in terms of mobility and range.

The Rise of Remote Work in Underwater Maintenance

The emergence of ROV technology has coincided with the broader trend of remote work, which has accelerated due to advances in communication technology and automation. Remote work in subsea operations refers to the ability for operators, engineers, and technicians to oversee and manage complex underwater tasks from a safe, onshore or offshore location—far from the hazardous conditions of the deep sea.

Before the advent of ROVs, underwater maintenance was a dangerous and resource-intensive process. Human divers were often used to inspect and repair subsea structures, but this method comes with significant risks, including exposure to extreme pressures, cold temperatures, and poor visibility. In addition, diving operations require extensive safety measures, specialized training, and costly logistics.

ROVs have dramatically transformed this scenario by providing a safer, more efficient alternative to human diving. With ROVs, operators can perform tasks such as inspecting pipelines, repairing damaged equipment, and monitoring subsea infrastructure remotely, all while maintaining complete control over the vehicle’s movements and tools.

Safety: Reducing Risks for Human Workers

Safety is one of the most significant advantages of using ROVs for underwater maintenance. Traditional methods of inspection and repair often involve human divers, who are exposed to high-risk environments, including:

- Decompression sickness (the bends) caused by rapid ascents.

- Drowning or sudden pressure changes that can lead to injury or death.

- Extreme cold temperatures and high-pressure conditions that increase the likelihood of accidents.

- Limited visibility and the challenging nature of underwater navigation, which can complicate tasks and increase the chance of error.

By using ROVs, the need for human divers is significantly reduced, eliminating many of these risks. ROVs can operate in environments where human divers cannot, such as extreme depths or hazardous conditions like strong underwater currents or low visibility. These vehicles are controlled by operators at the surface or from onshore locations, keeping human workers out of harm’s way.

Additionally, ROVs can be deployed quickly and can operate continuously for long durations without the need for rest or decompression. This allows for more frequent and comprehensive inspections, reducing the potential for costly repairs and increasing the overall safety of underwater infrastructure.

Efficiency: Streamlining Maintenance and Reducing Downtime

ROVs also offer significant improvements in efficiency. Offshore industries such as oil and gas, marine renewables, and subsea mining rely on subsea infrastructure to be operational at all times. Any downtime due to maintenance issues can result in substantial financial losses and environmental risks.

1. Real-Time Data Collection and Analysis

One of the key advantages of ROVs is their ability to transmit high-quality data back to the surface in real-time. Equipped with HD cameras, sonar, and environmental sensors, ROVs provide detailed visual and sensor data that allows operators to assess the condition of subsea structures as soon as issues arise. This real-time data enables rapid decision-making, making it easier for engineers to pinpoint problems and plan appropriate maintenance or repairs.

For example, ROVs equipped with ultrasonic testing tools or acoustic sensors can identify structural weaknesses or detect leaks in pipelines, all while transmitting data back to the operator. This eliminates the need for time-consuming physical inspections and reduces the risk of undetected damage leading to more significant issues.

2. Remote Operations and Monitoring

The shift to remote work has made it possible for operations teams to manage subsea maintenance and inspection projects from onshore locations or offshore control rooms, regardless of their physical distance from the worksite. This reduces the need for large offshore teams and specialized equipment, cutting operational costs while also improving logistical efficiency.

For example, a centralized control room can manage several subsea missions simultaneously by utilizing multiple ROVs. Technicians can monitor video feeds, receive sensor data, and control the ROVs’ movements, all without being physically present in the field. This remote monitoring helps reduce the costs associated with travel, accommodation, and logistics for offshore workers.

3. Continuous Operation and Reduced Downtime

ROVs, unlike human divers, can operate continuously without the need for breaks, making them ideal for long-duration tasks. Maintenance and inspection routines that once took days can now be completed in a fraction of the time, reducing the overall downtime of underwater operations. For example, a complex subsea pipeline inspection that might have required multiple divers or weeks of manual inspections can now be completed using ROVs within days, ensuring that the infrastructure remains operational and safe.

In addition, many modern ROVs are equipped with autonomous capabilities, which allow them to perform some tasks without human input. This increased autonomy means ROVs can operate in hazardous areas for extended periods, carrying out routine checks or performing minor repairs, while human operators focus on more complex decision-making tasks. This autonomous capability further enhances the efficiency and scalability of underwater operations.

4. Cost Savings and Operational Streamlining

The overall cost savings from using ROVs for underwater maintenance are significant. Traditional methods of underwater maintenance, such as sending divers into dangerous environments or deploying large support vessels, can be expensive and time-consuming. In contrast, ROVs can be deployed more quickly, with fewer personnel required on-site, and operate for extended periods without interruption.

Additionally, multi-tasking is made possible through the use of robotic arms, sonar, cameras, and specialized tools. This means that a single ROV can complete a variety of tasks, from inspections and repairs to data collection and environmental monitoring, eliminating the need for multiple vessels or teams to carry out different aspects of the work.

The Future of Remote Work and ROVs in Underwater Maintenance

As the world of work continues to evolve, ROVs are playing an increasingly important role in reshaping how maintenance and inspection are carried out in subsea environments. With advances in robotics, AI, machine learning, and communications technology, the future of remote underwater work holds exciting possibilities:

- Improved AI and Automation: Future ROVs will likely feature even greater levels of automation, allowing for fully autonomous operations with minimal human intervention. This will reduce the need for human oversight in routine inspections and maintenance, further reducing costs and risks.

- Greater Connectivity: As 5G and satellite communication technologies improve, ROVs will have access to faster and more reliable data transmission, enabling them to operate in real-time, even in the most remote underwater locations. This will enhance the capabilities of remote operators to perform complex tasks from anywhere in the world.

- Sustainability and Green Solutions: The growing emphasis on sustainability will drive the development of eco-friendly ROV technologies. Future ROVs will likely incorporate renewable energy sources, like ocean current-powered generators, to extend operational times without relying on traditional power sources.

Conclusion: A Safer, More Efficient Future for Underwater Maintenance

ROVs are leading the charge in making underwater maintenance safer, more efficient, and cost-effective. By enabling remote work in some of the most hazardous and remote environments on Earth, ROVs are reshaping subsea industries, reducing risks for human workers, and allowing for more efficient operations.

As robotics and remote work technologies continue to advance, ROVs will undoubtedly play an even more pivotal role in subsea operations, ushering in a new era of safety, efficiency, and sustainability for underwater maintenance.